Specialist Recommendations on Commercial Refrigeration Repair for Toronto Companies

Specialist Recommendations on Commercial Refrigeration Repair for Toronto Companies

Blog Article

Making Best Use Of Effectiveness: Commercial Refrigeration Repair Techniques for Cost-Effective Solutions

Assessing Refrigeration System Performance

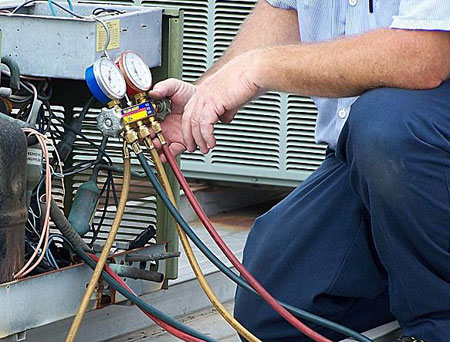

To successfully examine the efficiency of a commercial refrigeration system, it is important to carry out comprehensive assessments of its functional specifications and essential elements. The first step in analyzing system efficiency is checking out the functionality of the compressor.

Checking refrigerant levels and pressures is additionally essential in examining system efficiency. Low refrigerant degrees or abnormal stress can suggest leaks or malfunctioning components that require prompt interest to stop system failings and expensive fixings. By systematically assessing these operational parameters and essential components, businesses can ensure their business refrigeration systems operate at peak efficiency degrees, lessening downtime and making the most of power effectiveness.

Executing Preventative Maintenance Measures

Analyzing the efficiency of an industrial refrigeration system supplies valuable insights that can inform the execution of preventative upkeep actions important for maintaining optimal functionality and long life. Preventative upkeep is a positive approach aimed at identifying and attending to possible issues before they intensify right into pricey troubles that interfere with operations. By establishing a routine upkeep routine, refrigeration systems can run effectively, minimizing power consumption and reducing the danger of unforeseen break downs. Trick preventative maintenance procedures include checking and cleaning up condenser coils, inspecting cooling agent degrees, guaranteeing appropriate air flow, and adjusting temperature controls. Additionally, keeping track of temperature and humidity degrees, examining door seals, and dealing with any unusual sounds or smells promptly are necessary action in preventative maintenance. Executing these actions not just extends the lifespan of the devices but also enhances food security by maintaining regular storage space temperatures. Inevitably, purchasing preventative maintenance measures is a cost-efficient technique that assists organizations stay clear of pricey fixings and downtime, ensuring dependable and continuous refrigeration system performance.

Identifying Common Refrigeration Issues

One of the essential aspects in maintaining industrial refrigeration systems is without delay determining common issues that may arise throughout their operation. One widespread issue is inadequate air conditioning, commonly brought on by filthy condenser coils or a malfunctioning compressor. Normal cleaning of the condenser coils and making sure appropriate air flow around the device can help Visit Website avoid this concern. An additional common problem is refrigerant leaks, which can cause inefficient air conditioning and potential environmental threats. Keeping an eye on refrigerant degrees and conducting regular evaluations for leakages can assist reduce this problem. In addition, defective gaskets on doors, causing air leaks, can create the refrigeration system to work more difficult to keep the desired temperature level. Normal examination and substitute of damaged gaskets are important to avoid energy waste. Unusual sounds such as banging, clanking, or hissing can show underlying mechanical issues that need instant attention to stop further damages. By quickly recognizing and attending to these common refrigeration problems, companies can guarantee the reliable procedure of their systems and reduce costly fixings.

Making Use Of Energy-Efficient Repair Service Methods

When taking into consideration industrial refrigeration repair, implementing energy-efficient strategies is extremely important to enhancing the system's performance and reducing operational expenses. Among the essential strategies in attaining power efficiency is guaranteeing that the refrigeration system is properly kept. Normal maintenance, such as cleansing condenser coils, inspecting for cooling agent leakages, and calibrating temperature settings, can significantly boost energy efficiency.

Another energy-efficient repair service technique is upgrading to high-efficiency elements - commercial refrigerator repair. By replacing older, less reliable parts with energy-efficient options, such as ECM follower electric motors or LED illumination, businesses can decrease energy Clicking Here intake and lower energy costs. In addition, setting up programmable thermostats and energy monitoring systems can help control temperature levels better, avoiding unnecessary power usage

In addition, optimizing the system's insulation and sealing any leakages can likewise add to power savings. Correct insulation aids keep regular temperatures within the refrigeration system, reducing the workload on the system and enhancing total performance. By integrating these energy-efficient repair work strategies, businesses can not just reduce their ecological effect however likewise attain long-term expense savings.

Optimizing Refrigeration System Life Expectancy

To guarantee the longevity and optimum performance of industrial refrigeration systems, maintaining energy-efficient repair service practices is vital, with a focus currently shifting in the direction of making the most of the refrigeration system life-span. Maximizing the life expectancy of a refrigeration system entails aggressive upkeep, timely fixings, and adherence to producer guidelines.

Furthermore, educating staff on proper system operation and upkeep click to investigate practices can add to the long life of the tools. Educating workers to report any unusual noises, leakages, or changes in performance can assist in capturing issues in their first phases. In addition, spending in high-grade components and elements during repair services and replacements can enhance the durability of the refrigeration system. By prioritizing aggressive maintenance and making use of quality parts, organizations can enhance the life expectancy of their industrial refrigeration systems, inevitably lowering downtime and operational costs.

Final Thought

Finally, by routinely analyzing refrigeration system efficiency, executing preventative maintenance steps, identifying common refrigeration issues, using energy-efficient repair techniques, and maximizing the system's life expectancy, businesses can optimize efficiency and minimize expenses connected with business refrigeration fixing. These economical solutions help to ensure that refrigeration systems run at peak efficiency, ultimately bring about boosted performance and earnings for organizations in the future.

When taking into consideration industrial refrigeration repair, applying energy-efficient strategies is critical to enhancing the system's performance and reducing operational prices.To ensure the durability and optimal performance of commercial refrigeration systems, keeping energy-efficient repair techniques is crucial, with a focus currently moving towards making the most of the refrigeration system life-span. Optimizing the life expectancy of a refrigeration system entails aggressive upkeep, timely repair services, and adherence to maker standards.

Report this page